On the N47 4-cylinder diesel engine, the exhaust gas recirculation is controlled with an EGR actuator operated with a partial vacuum.

Depending on the operating status, a certain quantity of exhaust gas is returned via the EGR valve into the exhaust tract. This reduces the nitrogen oxide emissions. The EGR control is only active at low engine speeds and loads:

In contrast to the diesel engines used to date, a position sensor is fitted on the partial-vacuum canister of the EGR actuator, enabling an adjusting path acknowledgement.

EGR control

The quantity of recirculated exhaust gas influences the mass of the fresh air drawn in: The more exhaust gas is recirculated, the less fresh air is drawn in. The mass of fresh air that passes through the engine at any point on the performance curve when the EGR is switched off is a known quantity. Thus the reduction in the mass of fresh air drawn in due to exhaust gas recirculation is a measure of the quantity of exhaust gas recirculated. During operation, the pulse duty factor on the pressure converter is controlled in such a way that the specified fresh air mass for the operating point concerned is drawn in.

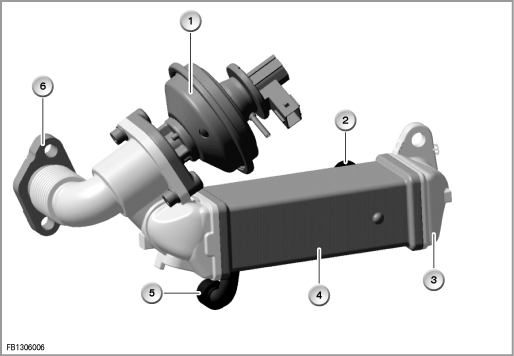

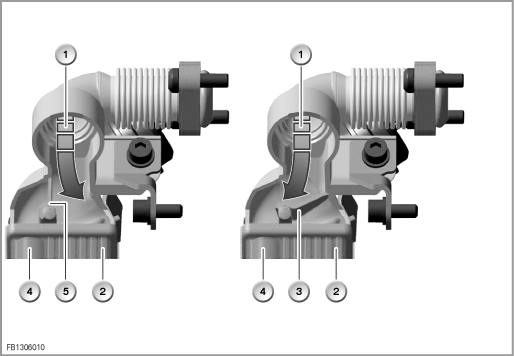

Fig. 1: exhaust gas recirculation assembly

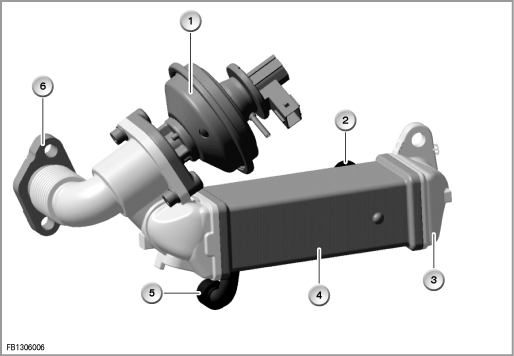

Fig. 2: exhaust gas recirculation assembly, variant with bypass flap in the EGR cooler

Mean quantity adaptation

The quantity mean value adaptation serves to adapt the exhaust gas recirculation more precisely to tolerance in the fuel injection rates.

The lambda value measured by the oxygen sensor and the air mass measured by the HFM are used to determine a mean fuel injection rate across all cylinders. This value is compared with the fuel injection rate specified by the DDE control unit. If there is a deviation, the air mass is adapted to the actual fuel injection rate by adjusting the exhaust gas recirculation valve in such a way that the correct lambda value is set. The MMA is not a rapid control operation, rather an adaptive learning procedure. That means that the fuel injection rate error is learned in an adaptive characteristic map that is stored permanently in the DDE control unit.

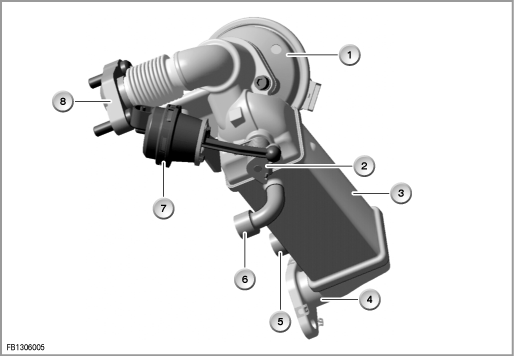

Fig. 3: exhaust gas recirculation valve

The vacuum unit is connected to the vacuum supply via the pressure converter. The applies a variable vacuum to the vacuum unit according to the commands received from the DDE control unit. The DDE control unit controls the pressure converter by means of a square-wave signal with a pulse duty factor (= variable pulse width) between 50 % and 75 %.

The maximum stroke of the exhaust gas recirculation valve is 8 ± 0.5 mm.

The DDE uses the EGR position sensor to measure the adjusting path of the EGR valve. The adjusting path of the exhaust gas recirculation valve is used as an additional input variable for EGR control.

The position sensor is a linear potentiometer and is supplied with a voltage of 5 V. The voltage signal of the position sensor is converted in the DDE and output as a percentage value.

In order lower the temperature of the recirculated exhaust gas and thus further reduce nitrogen oxide emissions, the exhaust gas is returned through the EGR cooler.

Bypass flap for EGR cooler

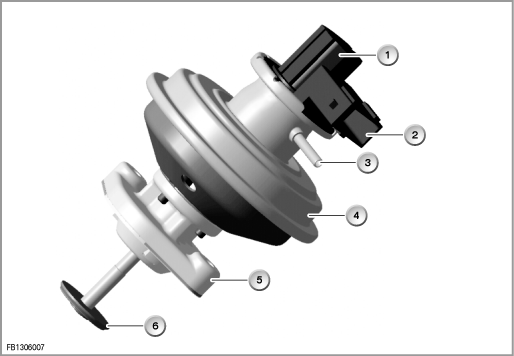

Fig. 4: bypass flap in EGR cooler

In vehicles with N47oL and manual gearbox, there is a bypass flap in the EGR cooler. With this flap, the exhaust gas is guided at low temperatures past the cooling slits into a bypass channel and thus not cooled. Only at higher engine temperatures does the DDE open the bypass flap and the exhaust gas is cooled again.

This function reduces the HC emissions in cold operating states. It also prevents soiling in the EGR cooler by exhaust gas residues. This measure is necessary in the case of vehicles with N47oL and manual gearbox because the temperature level is generally lower than on the other variants.

The bypass of the EGR cooling is opened during EGR operation if the coolant temperature is lower than 50 °C.

A oxygen sensor is required for the quantity mean value adaptation function. The oxygen sensor is fitted immediately after the turbine of the exhaust turbocharger. The oxygen sensor, familiar from petrol engines, is a wide-band sensor that provides exact lambda values over a wide measuring range.

Resetting the quantity mean value adaptation

The service function 'quantity mean value adaptation' must be run if one of the following components was replaced:

Description and sequence of the service function, see corresponding functional description.

Adaptation of EGR valve

If the exhaust gas recirculation valve is replaced, the following service function must be run before the replacement:

Description and sequence of the adaptation, see corresponding functional description.