Dynamic Drive prevents or reduces the vehicle's tendency to roll while cornering. Vibration comfort is increased. The turn-in ability of the vehicle is optimised.

The following components are described for Dynamic Drive:

The functions of the control unit are controlled by a microprocessor. The control unit is supplied via terminal 30 with voltage (with 10 A fuse). The control unit is activated via the wake-up line (terminal 15).

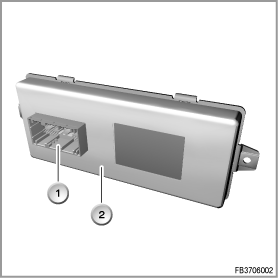

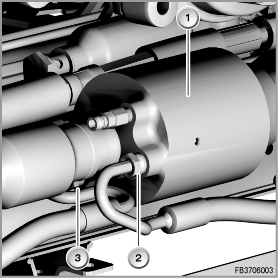

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Connector for Dynamic Drive |

2 |

Control unit for Dynamic Drive |

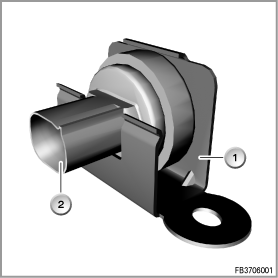

The following valves are integrated in the valve block:

The valve block is located in the right front wheel arch near the A pillar. It performs the following tasks:

Two pressure control valves (one each for the front and rear axle) split the oil flow. The oil flow then leads to the hydraulic motors. The pressure at the front-suspension hydraulic motor is greater than or equal to the pressure at the rear-suspension hydraulic motor.

Measuring the actual pressures of the high-pressure oil: There is a pressure sensor at each of the valve-block outlets for the front and rear-suspension hydraulic motors.

The direction of rotation of the two hydraulic motors is set by a shared direction valve. The position of the direction valve is detected and monitored by means of a switch position sensor.

In the following cases, the front-suspension hydraulic motor is sealed and locked. Can be drawn in from the fuel line via the non-return valves.

Can be drawn in from the fuel line via the non-return valves.

The transverse acceleration measured is the most important determining variable for the function of Dynamic Drive. The zero point of the transverse acceleration sensor can be learned in the corresponding service function by means of a diagnosis command from the Dynamic Drive control unit.

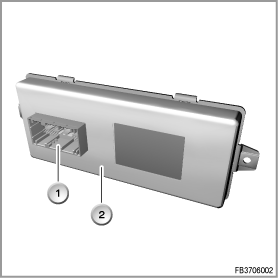

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Transverse acceleration sensor |

2 |

Connector for transverse acceleration sensor |

The pressure sensors are located on the valve block. The zero point values of the pressure sensors are learned via diagnosis commands in the corresponding service function from the Dynamic Drive control unit.

The switch position sensor is located on the valve block and it detects the position of the direction valve.

The pressure control valves are located in the valve block. The pressure control valves are electrically operated. This sets the pressure for the front and rear-axle anti-roll bars. When the vehicle is travelling in a straight line, the pressure control valves are de-energised. The oil flow to the reservoir is not restricted. On cornering, the valve are supplied with current. The pressure in the hydraulic motors rises and is adjusted to the target value.

The direction valve is located in the valve block. The directional control valve is electrically operated. The direction valve sets the direction of flow of the oil for left and right-hand bends. A switch position sensor monitors the position of the direction valve.

The safety valve is located in the valve block. The safety valve is electrically activated and when de-energised shuts off the hydraulic motor of the front axle.

The non-return valves are located in the valve block. The check valve permit oil to be drawn in. This prevents cavitation in the hydraulic motor.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Directional control valve |

2 |

Pressure sensor, rear axle |

3 |

Proportional pressure limiting valve, front axle |

4 |

Proportional pressure limiting valve, rear axle |

5 |

Pressure sensor, front axle |

6 |

Switch position sensor |

7 |

Safety valve |

|

|

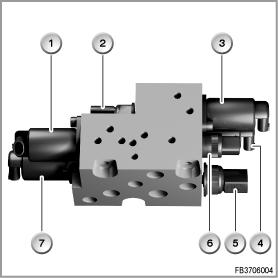

The active anti-roll bars are vertically split in the middle. The active anti-roll bar consists of a hydraulic motor and, attached to it, the two halves of the anti-roll bar with press-fitted roller-bearing mountings. The hydraulic motor shaft and housing are each attached to one half of the anti-roll bar. In the hydraulic motor, the opposing chambers are linked. This means the chambers each have the same pressure. Two chambers are supplied with high pressure via one connection. The two other chambers are connected to the return line to the expansion tank. Variation of the pressure varies the force generated by the motor. That force produces torque which rotates the shaft relative to the housing. As one half of the anti-roll bar is attached to the shaft and the other to the housing, the two halves of the anti-roll bar then twist in opposite directions to one another. The momentum that this creates counteracts / stabilises the rolling motion. The maximum system pressure is 180 bar.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Front hydraulic motor |

2 |

Hydraulic connection |

3 |

Hydraulic connection |

|

|

The tandem pump supplies the oil circuit of the Dynamic Drive as well as the power steering. The pump consists of a radial piston for the Dynamic Drive system and a vane pump for the power steering. Dynamic Drive and the power steering share a common oil cooler and oil reservoir.

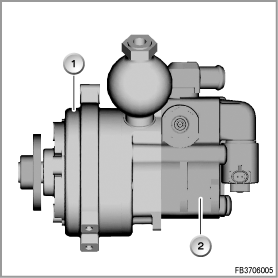

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Radial piston section of the tandem pump |

2 |

Vane cell section of the tandem pump |

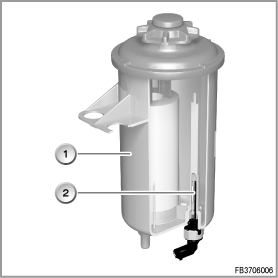

The oil reservoir has an integrated filter and oil-level switch. If the oil level drops below the minimum mark, a signal is sent to the Dynamic Drive control unit.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Oil tank |

2 |

Oil-level switch |

The oil cooler keeps the oil temperature below 120 °C. The oil temperature is allowed to rise to a maximum of 135 °C for short periods.

The following system functions are described for Dynamic Drive:

The Dynamic Drive controls the two active stabiliser bars according to the transverse acceleration levels detected. By so doing, it reduces body roll when cornering and on uneven road surfaces.

The Dynamic Drive control unit calculates from the input signals the commands that need to be sent to the hydraulic motors. The input signals are also checked for plausibility and used for system monitoring purposes.

The most important control variable is the lateral acceleration. The following PT-CAN signals are also analysed:

This additional information improves the system's response time.

The control unit has short circuit-proof outputs for:

The valves are activated via current control (pulse-modulated signal). Signals are sent across the PT-CAN to the engine DME/DDE indicating whether additional power is required. This is the only way the power requirement can be covered, for example when idling during the commissioning procedure.

Dynamic Drive is not active with the vehicle stationary. All valves are without current. In other words, when the vehicle is stationary, the active anti-roll bars do not generate any torque. If the vehicle is leaning to one side when parked (e.g. with two wheels on the kerb or unevenly loaded), the system does not perform any adjustments despite the fact that there is a measurable lateral force. The Dynamic Drive comes into action at speeds upwards of approx. 15 km/h.

Warning! Rolling motion on commissioning

During commissioning, the vehicle performs very strong and rapid rolling motions. For this reason, no persons may be located directly at the vehicle, particularly in the proximity of moving vehicle components. There must be no objects underneath the vehicle or in the wheel arches! The commissioning procedure may only be carried out with the vehicle standing of a firm, flat surface with all four wheels on the ground. Under no circumstances may the commissioning be carried out on

Disregarding these instructions could put lives at risk!

After opening the system hydraulics, i.e. after working on the

commissioning is to be run. After coding or programming the Dynamic Drive control unit, commissioning is also required.

Commissioning

The purpose of commissioning is to teach the parameters and zero point of all sensors. Commissioning is divided into 5 phases and it takes around 25 seconds.

Note! Temperature on commissioning

The oil temperature is an important parameter for the commissioning. The commissioning procedure (by means of diagnosis command) must not be carried out at extreme temperatures (ambient and system temperatures).

After coding or programming the control unit, commissioning is to be run.

The following warnings and their causes can appear as Check Control messages in the CID:

With the warnings:

the Dynamic Drive system has been switched off.

NB: the vehicle tilts more strongly in bends than a vehicle without the Dynamic Drive System. Precondition for continued driving to the next workshop:

Possible causes of the warning message:

In order to be able to pinpoint the cause more exactly, read the fault code memory and run through the displayed test plan. When the fault has been remedied, delete the fault code memory.

With the warning:

the driver is informed that the vehicle has suffered oil loss in the chassis and steering system.

In this case, it is not possible to continue driving to the next workshop.

Possible causes of the warning message:

In order to be able to pinpoint the cause more exactly, read the fault code memory and run through the displayed test plan. When the fault has been remedied, delete the fault code memory.

With the warning:

the driver is notified that the chassis stabilisation from Dynamic Drive is restricted, but it is possible to continue driving.

A workshop should be contacted at the next opportunity.

Possible causes of the warning message:

In order to be able to pinpoint the cause more exactly, read the fault code memory and run through the displayed test plan. When the fault has been remedied, delete the fault code memory.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature