Petrol engines with direct fuel injection have a fuel low pressure system (fuel tank, electric fuel pump) and a fuel high pressure system (high-pressure fuel pump, fuel-supply control valve, rail with rail-pressure sensor).

The following components are described:

The high-pressure fuel pump compresses the fuel (range of 50 to 200 bar) and feeds it to the rail.

The high-pressure fuel pump is bolted onto the rear end of the vacuum pump. The drive shaft of the high-pressure fuel pump is connected to the drive shaft of the evacuating pump.

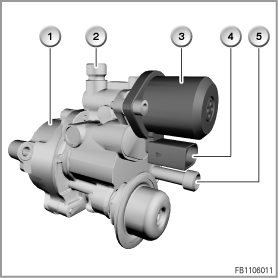

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

High-pressure fuel pump |

2 |

Connection for the high pressure line to the rail |

3 |

Volume control valve |

4 |

Electrical connection |

5 |

Connection for the low pressure line from the fuel pump |

|

|

The volume control valve controls the fuel delivery pressure in the rail. The volume control valve is activated via a pulse-modulated signal (PWM signal) from the DME control unit. Depending on the PWM signal, various throttle cross-sections are released and the necessary fuel supply volume for each engine load is set. In addition, there is the possibility to reduce the pressure in the rail.

If a fault in the system is diagnosed, e.g. failure of the high-pressure sensor, the current to the volume control valve is cut off. The fuel then reaches the rail via a so-called bypass valve.

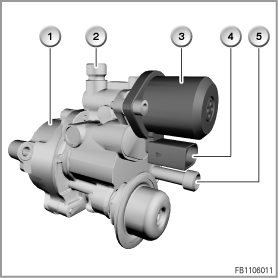

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

High-pressure fuel pump |

2 |

Connection for the high pressure line to the rail |

3 |

Connection for the low pressure line from the fuel pump |

4 |

Volume control valve |

5 |

3 Pistons as well as intake and exhaust valves |

6 |

Pressure relief valve |

7 |

Bypass valve |

|

|

The volume control valve is a component of the high-pressure pump and can be removed during service.

In the rail, the compressed fuel is stored temporarily and distributed to the injectors.

The rail-pressure sensor measures the current fuel delivery pressure in the rail.

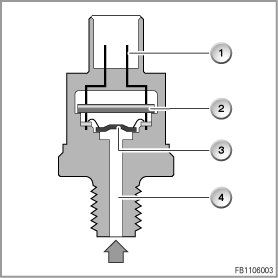

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Electrical connection |

2 |

Evaluating circuit |

3 |

Membrane with sensor element |

4 |

High-pressure connection |

The fuel delivery pressure passes through the high-pressure connection to the membrane with sensor element. The deformation of the membrane is converted via the sensor element into an electrical signal. The evaluating circuit processes the signal and forwards an analog voltage signal to the DME. The voltage signal rises in linear form with increasing fuel delivery pressure.

The signal from the rail-pressure sensor is an important input signal of the DME for activation of the volume control valve (component of the high-pressure pump).

If the rail-pressure sensor fails, the volume control valve is activated in emergency operation by the DME.

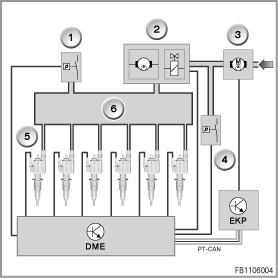

The following system functions are described:

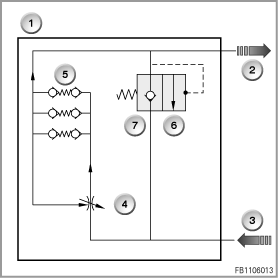

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Rail pressure sensor |

2 |

High-pressure pump with volume control valve |

3 |

Electrical fuel pump |

4 |

Fuel low pressure sensor |

5 |

Fuel injectors |

6 |

Rail |

EKP |

Electric fuel pump control unit |

DME |

Digital Engine Electronics |

PT-CAN |

Powertrain CAN |

|

|

According to system pressure applied between the fuel pump and high-pressure pump, the fuel low pressure sensor sends a voltage signal to the engine control unit (DME control unit).

The system pressure (fuel low pressure) is determined with the fuel low pressure sensor before the high-pressure pump.

The DME control unit runs a continuous comparison between the specified pressure and actual pressure. If there is a deviation between the specified pressure and actual pressure, the DME control unit increases or decreases the voltage for the electric fuel pump, sent as a message across the PT-CAN to the EKP control unit. The EKP control unit converts the message into an output voltage for the electric fuel pump. These regulates the required delivery pressure for the engine (or high-pressure pump).

In the event of a signal failure (fuel low pressure sensor), with terminal 15 On the electric fuel pump is operated with pre-control.

If the CAN bus fails, the electric fuel pump is operated via the EKP control unit with the prevailing on-board supply voltage.

The high-pressure pump compresses the fuel to a pressure between 50 and 200 bar. The compressed fuel reaches the rail via the high pressure line. In the rail, the compressed fuel is stored temporarily and distributed to the injectors.

The rail-pressure sensor measures the current fuel delivery pressure in the rail. When the volume control valve in the high-pressure pump opens, the excess fuel delivered is returned to the inlet.

If the high-pressure pump fails, restricted driving is possible.

Warning! Only work on the fuel system when the engine is cold.

At coolant temperatures above 40 °C, fuel can emerge at high speed when the injectors are loosened.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature