As series standard, the E70 is equipped with an electromechanical parking brake (EMF). The parking brake is the same as a handbrake. The parking brake is familiar from the BMW 7 Series. The parking brake is operated using the parking brake button in the centre console.

The configuration of the parking brake meets the following requirements:

The parking brake serves to secure the stationary vehicle against rolling away.

When the engine is off, the EMF engages the parking brake: electromechanically via the actuating unit.

With the engine running, the dynamic stability control (DSC) engages the parking brake: hydraulically via the 4 wheel brakes.

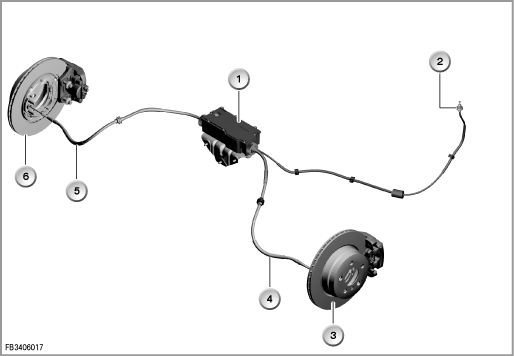

The following components are described for the parking brake:

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Actuating unit |

2 |

Emergency release |

3 |

Wheel brake, rear left |

4 |

Bowden cable, left |

5 |

Bowden cable, right |

6 |

Wheel brake, rear right |

The actuating unit is attached to the rear-axle member.

The actuating unit is parking brake is sealed and water-tight. The housing cannot be opened in service.

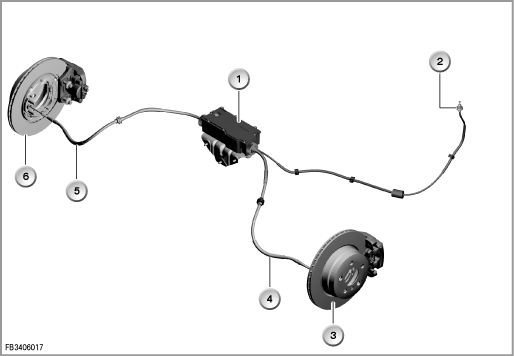

The actuating unit consists of:

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

EMF control unit |

2 |

Electric motor |

3 |

Emergency release |

4 |

Bowden cable, left |

5 |

Gearing |

6 |

Force sensor |

7 |

Bowden cable, right |

|

|

The rear distribution box supplies the EMF with voltage (terminal 30 twice).

The Bowden cables are adjusted electromechanically via the electric motor with flanged-on gearing. Here, each of the Bowden cables act on an expander lock that sets the drum brake on the back wheel.

The force sensor delivers the EMF control unit the actuating force. Recording the actuating force is necessary to ensure the required brake force.

A spring is integrated in the force sensor, in which the Bowden cables end. The force sensor measures the travel when the springs are compressed. The travel measurement is based on the Hall effect.

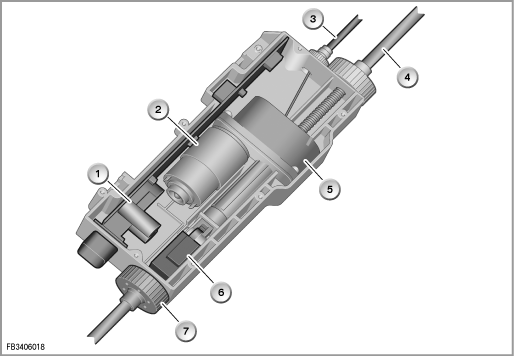

The parking brake button is located in the centre console behind the gear selector switch (GWS). The design of the parking brake button is based on the operations logic of a handbrake:

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Parking brake button |

2 |

Gear selector switch (GWS) |

3 |

Sport button |

|

|

An indicator lamp in the instrument cluster shows that the parking brake has been activated.

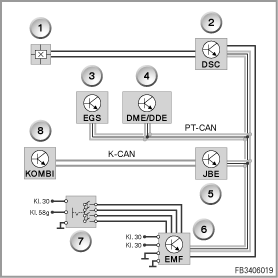

The following additional control units are involved in the electromechanical parking brake (EMF):

The dynamic stability control (DSC) is the master control unit for the electromechanical parking brake (EMF).

With the engine running, the dynamic stability control (DSC) engages the parking brake. The DSC also delivers the conditioned wheel-speed (front left) from the active wheel-speed sensor. The signal is transferred across a separate line. The signal is particularly important for detection of the vehicle standstill.

In addition, the DSC sends the driving speed as a plausibility check (averaged over the 4 wheel-speed sensors) on the PT-CAN. In addition to the plausibility check, the gearbox output speed of the automatic gearbox is used.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Wheel-speed sensor, front left |

2 |

DSC (Dynamic Stability Control) |

3 |

Electronic Gearbox Control (EGS) |

4 |

Digital Engine Electronics /or Digital Diesel Electronics |

5 |

Junction box electronics (JBE) |

6 |

Electromechanical parking brake (EMF) |

7 |

Parking brake button |

8 |

Instrument cluster (KOMBI) |

Via DSC, dynamic emergency braking can also be initiated with the parking brake button.

The engine management system delivers the signal ”Engine running”. The signal is transferred across the PT CAN.

The electrical gearbox control delivers the following signals:

In the event of failure of or a fault in the EMF, the warning and indicator lamp for the EMF lights up. In addition, a Check Control symbol is displayed in the LC display.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Warning and indicator lamp |

2 |

Check Control symbol |

If there is a Check Control message, additional supplementary instructions can be displayed on the Central Information Display (CID).

The junction box electronics (JBE) form the gateway between the PT-CAN and K-CAN.

The following system functions are described for the parking brake:

The brake is engaged by pulling the parking brake button.

With the engine running or rolling vehicle:

via the DSC, the handbrake is applied hydraulically on the disc brakes of the front and rear axles.

With the engine off and the vehicle stationary:

the parking brake is applied with the help of the electromechanical actuating unit via Bowden cables to the drum brakes of the rear axle.

Driving off against the blocked brake pressure leads to another pressure increase and a Check Control message.

Starting the engine leads to a switch from electromechanical to hydraulic parking brake engagement.

The parking brake is disengaged by pressing the parking brake button.

The active brake system opens.

When the vehicle is stationary and the engine is running or off, it is only possible to disengage the parking brake with the brake pedal operated.

With the engine off (via bus signal ”status engine running”), there is a switch from hydraulic to electromechanical engagement of the parking brake.

If the parking brake button is pulled while the vehicle is being driven, hydraulic braking occurs for 0.8 s with 3 m/s2. For the next 2 seconds, the braking power is increased (linear) to 5 m/s2.

As long as the vehicle is rolling and the engine is running, emergency braking is handled by the hydraulic components. With the engine off and the vehicle stationary, emergency braking is handled by the mechanical system.

The braking is maintained by the DSC for as long as the parking brake button is pulled.

Here, all DSC control operations are run as if via the brake pedal.

As the dynamic emergency braking acts hydraulically on all 4 wheels, significantly greater decelerations with a minimum of actuating force are possible compared to conventional parking brakes. For safety reasons, the following traffic is warned by the brake lights in the event of dynamic emergency braking. Dynamic emergency braking via the handbrake is intended for emergencies and under no circumstances does it replace braking with the brake pedal.

If braking by the brake pedal and parking brake overlap, the DSC decides on the higher specified value. On emergency braking to vehicle standstill, the vehicle remains hydraulically braked even after the parking brake button is released. It is only when the parking brake button is pressed again that the hydraulic brake is released.

Roll monitoring prevents the vehicle with engaged parking brake from rolling away. The roll monitoring observes the wheel-speed signals of the braked wheels after the parking brake has been applied. The wheel-speed signal indicates that the vehicle is rolling away. If rolling away is reliably determined, the activated brake system re-tensions the brakes.

The roll monitoring is disabled on:

This function activates the mechanical brake application if the vehicle has to be additionally safeguarded when the hydraulic brake has been applied (e.g. driver leaves the vehicle).

The DSC control unit detects when the driver leaves the hydraulically braked vehicle (CAN message, e.g. via seat occupation detection). The DSC then requests the EMF to add mechanical brake application.

The EMF releases the additional braking when signals arrive that indicate the driver has returned.

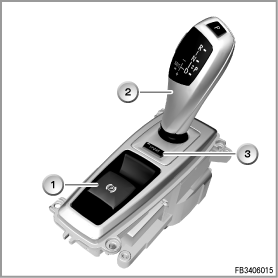

In the event of failure of the EMF (e.g. fault code memory entry) or inadequate power supply, a mechanical emergency release is implemented. The emergency release mechanism enables manual release of the actuating unit.

Important! Secure against rolling away.

Before operating the emergency release, secure the vehicle against rolling away.

Emergency release is performed manually by means of a Bowden cable and a handle from the on-board tool kit. The actuator for the drum brake is released in the actuating unit.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Bowden cable emergency release |

2 |

Handle for emergency release in the on-board tool kit |

After emergency release of the parking brake, it might be that the vehicle still cannot be moved after an interruption to the power supply. The parking lock of the automatic gearbox might still be engaged.

When the parking brake has been emergency-released:

apply strong pressure to the brake.

After ignition ON, press the parking brake button downwards once.

The emergency release is locked. The parking brake closes automatically. This runs a detection of a cable break via the force sensor. Subsequently, the parking brake opens automatically.

Important! Replace the brake shoes of the parking brake.

After replacement of the brake shoes on the drum brake, braking-in is required. For this, a service function is available in the BMW diagnosis system

.

The following service functions are available in the BMW diagnosis system:

Note! The sound on engaging the actuating unit is very quiet.

If engaging and disengaging the parking brake were detected, the fault code memory of the EMF must be deleted subsequently.

Note! Fault code memory entry in the DSC.

After replacement of the parking brake, the DSC has a fault code memory entry (interface).

After replacement of the actuating unit, the EMF control unit must be coded.

The indicator lamps in the instrument cluster as well as the Check Control symbols are designed as country-specific.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature