Power supply E70

Power supply E70

A composite unit of hardware and software ensures the power supply

for the vehicle systems. Essential for the power supply

are two software functions:

- Energy management

- Power management

The energy management ensures that sufficient starter motor current is always available.

The

energy management monitors the vehicle even with the engine at a standstill.

The

energy management includes all components in the vehicle that generate, store and consume energy.

The data for the energy management is distributed across a number of control units.

The power management a subsystem of the

energy management.

The power management is run from the engine control unit

(DME or DDE: Digital Engine Electronics or Digital Diesel Electronics).

While the vehicle is being driven, the power management regulates the power output of the alternator

as well as the battery charging.

Brief description of components

The following components for power supply

are described:

- Battery

- Alternator

- Junction Box Electronics

- Distribution box

- Intelligent battery sensor

- Car Access System

- Digital Engine Electronics /or Digital Diesel Electronics

- Multiple restraint system

- Bit-serial data interface

- Battery cables

- Relay box

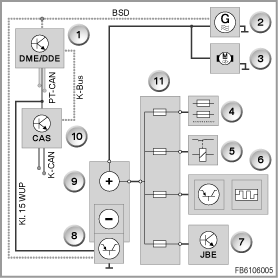

System circuit diagram

Index

|

Explanation

|

Index

|

Explanation

|

1

|

DME (Digital Engine Electronics) or DDE (Digital Diesel Electronics)

|

2

|

Alternator

|

3

|

Starter motor

|

4

|

Rear distribution box

|

5

|

Relay box

|

6

|

Electrical auxiliary heater (only on version

with diesel engine)

|

7

|

Junction box electronics

(JBE) with distribution box at the front

|

8

|

Intelligent battery sensor (IBS)

at the negative battery terminal

|

9

|

Positive battery terminal

|

10

|

Car Access System (CAS)

|

11

|

Fuse block

|

|

|

BSD

|

Bit-serial data interface

|

Terminal. 15 WUP

|

Wake-up line (terminal 15

wake up)

|

K bus

|

Body bus

|

K CAN

|

Body CAN

|

PT-CAN

|

Powertrain CAN

|

|

|

Battery

The capacity of the built-in battery depends on

the engine used and the vehicle equipment. Selection criteria

for the required capacity are:

- the cold-start characteristics

of the engine

- the closed-circuit current consumption of the vehicle

- the energy requirement of the auxiliary consumer units (independent heating,

telephone, etc.)

Alternator

With the engine running, the alternator generates a variable

charge voltage for battery charging.

The variable charge voltage

is influenced by the power management depending on the temperature and current by the DME/DDE raising the engine speed.

JBE: Junction Box Electronics

The JBE is the central data interface in the vehicle

(gateway for the buses).

The JBE is a component of the junction box. The junction box is an assembly consisting of the junction box electronics

and front distribution box. The front distribution box and JBE can not

be replaced individually.

The distribution boxes contain fuses and relays. Particularly important for

the power supply are the following relays:

- Relay terminal 15

(rear distribution box)

- Relay terminal 30g for consumer unit shutdown (rear and front distribution boxes)

- Relay terminal 30g-f for

cutoff in the event of faults (rear distribution box)

Distribution box

There are the following distribution boxes:

- Distribution box in the engine compartment:

E-box

- Distribution box at front in the junction box

- Rear distribution box

- Fuse block

The fuse block can only be completely replaced.

The fuses can not be replaced individually.

The fuse block contains fuses

for the following consumer units:

- Valvetronic

- Common rail (fuel injection on diesel engine)

- Electric auxiliary heater

- Distribution at front in the junction box electronics

- Rear distribution box

- Intelligent battery sensor

- Electric fan (8-cylinder diesel engine)

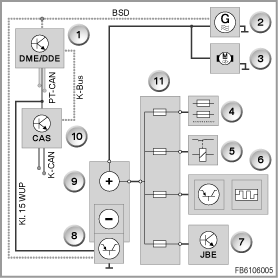

IBS: Intelligent battery sensor

The IBS is a mechatronic, intelligent battery sensor

with its own microprocessor. The microprocessor is a component of the

electronic module. The electronic module records the voltage,

the current flowing and the temperature of the battery.

The following components are fitted in the electronic module:

- a shunt (resistor

for current measurement)

- a temperature sensor

- electronic evaluation unit on a board

The IBS continuously measures the following values on the battery:

- Terminal voltage

- Charge current

- Discharge current

- Temperature of the battery

For data transmission, the IBS is connected to the DME (Digital Engine Electronics) or DDE (Digital Diesel Electronics) via the BSD (bit-serial data interface).

Index

|

Explanation

|

Index

|

Explanation

|

1

|

Measurement of the battery voltage between

the positive battery terminal and negative battery terminal

|

2

|

Temperature measurement of the battery (T)

|

3

|

Microprocessor (C) in the intelligent

battery sensor (IBS)

|

4

|

Digital Engine Electronics (DME) or

Digital Diesel Electronics (DDE)

|

5

|

Current measurement (A) [indirect, via

the proportionally voltage drop (V) at the measuring resistance (shunt)]

|

6

|

Negative battery terminal

|

7

|

Positive battery terminal

|

|

|

BSD

|

Bit-serial data interface (BSD)

for transfer of the values to the DME or DDE

|

|

|

This measurement data is queried while the vehicle is being driven and when the vehicle is at a standstill:

- Vehicle being driven:

- Calculation of the battery status

as basis for the battery charge state (SOC: ”State

of Charge”) and battery condition (SOH: State of Health”).

Balancing the charge and discharge current of the battery.

Continuous monitoring

of the battery charge state and transfer of the data.

- Calculation of the current characteristics on engine start

to ascertain the battery condition.

While the vehicle is being driven, the IBS transfers the data across the bit-serial data interface (BSD) to the engine control unit (DME/DDE). The software in the IBS controls the communication with the higher-level

engine control unit (DME/DDE).

- Vehicle at a standstill

When the vehicle is at a standstill, the measured values are queried in cycles

to detect energy losses.

The IBS is

programmed in such a way that it wakes up every 40 seconds to update the measured values with a new measurement. The measurement takes approx. 50 milliseconds (ms). The

measured values are entered in the IBS in the memory for recording the closed-circuit current.

After restarting the engine, the DME/DDE

reads out the course of the closed-circuit current. If there is a deviation from the defined

course of the closed-circuit current, an entry is made in the fault code memory

of the DME/DDE.

CAS: Car Access System

The Car Access System participates in the terminal control (terminal R, terminal 15, terminal 30g).

The

terminal control delivers essential messages for the power supply.

The CAS is connected to the following components and control units:

- The Car Access System is connected by a direct cable

with the START-STOP button and with the insert compartment

for the identification sensor.

The START-STOP button

and the insert compartment are beside the steering column.

- The starter motor and the DME or

DDE are connected to the CAS.

The CAS control unit is equipment attached to the bus

on the K-CAN.

DME or DDE: Digital Engine Electronics /or Digital Diesel Electronics

The DME or DDE contribute to the power supply as follows: If the alternator voltage falls, DME/DDE

increase the engine speed depending on the requirement. The software for this is called ”power management”.

The DME/DDE is equipment attached to the bus on the PT-CAN

(Powertrain Controller Area Network).

The DME/DDE evaluates the current battery condition.

This means that the DME/DDE also influences terminal 30g-f.

MRS: Multiple restraint system

If the restraint systems trigger,

the MRS control unit sends a message to other control units. Depending on the severity of the accident, e.g. the DME switches off the electric fuel pump.

Bit-serial data interface

The bit-serial data interface is the data line

between the engine control unit (DME or DDE) and the alternator.

Battery cable

2 battery cables connect the battery with

the engine compartment:

- One of the battery cables

leads across the starting-aid terminal to the

starter motor and to the alternator. This battery cable is monitored by the

crash safety module.

- The other cable is for the power supply

and it leads to the fuse block.

Relay box

What is fitted depends on the

engine and national version.

- Valvetronic relay

on petrol engines

- Secondary air pump relay (only US version

with petrol engine)

- Relay for common rail (only diesel engines)

System functions

The following system functions are described for the power supply:

- Power management (”Advanced

Power Management”)

- Emergency operation on failure of the bit-serial data interface

- Energy management

Power supply for the control units, consumer shutdown

of auxiliary consumer units as well as closed-circuit current monitoring

- Data interchange for the

power supply

Power management

Power management is software in the engine control unit

(DME/DDE: Digital Engine Electronics or Digital Diesel Electronics).

The power management calculates the target values for control of the power supply.

For the model series E70, exclusively Advanced Power Management (APM) is deployed.

Advanced Power Management

Index

|

Explanation

|

Index

|

Explanation

|

1

|

Advanced Power Management (APM)

|

2

|

Data of the battery:

- Current

- Voltage

- Temperature

|

3

|

Intelligent battery sensor (IBS)

|

4

|

Engine

|

5

|

Consumer units

|

6

|

Alternator (G)

|

7

|

Battery

|

8

|

Specified target value for charge voltage

|

9

|

Consumer shutdown or reduction

of power consumption

|

10

|

Increase in idle speed

|

The main factor for the greater

range of functions of the Advanced Power Management is the intelligent battery sensor (IBS). The IBS provides the power management with information on the battery status. Calculation of the temperature of the battery

using the outside temperature is no longer necessary.

The temperature of the battery is measured directly by the IBS.

The Advanced Power Management can perform the following functions:

- Increase in idle speed

On vehicles with petrol engines, the idle speed is raised by up to 200 rpm as soon as power is taken from the battery despite the alternator having maximum load.

On diesel engines, no idle-speed increase

is required. Reason: between the alternator and combustion engine, the

final drive ratio is higher than on a

petrol engine. This means the alternator has a high speed even at idle speed.

The power output of the alternator

is also high at idle speed. Raising the speed is

not necessary.

- Optimised charge voltage

The alternator voltage is regulated depending on the calculated temperature of the battery.

The

temperature of the battery is calculated on the basis of the outside temperature. According to the temperature of the battery, the target values

for the charge voltage are calculated. This information is sent across the bit-serial data interface to the regulator in the alternator.

- Battery test

- Energy diagnosis

- Deactivation of individual consumer units or reduction

of the power consumption

On vehicles with IBS, if required consumer units

are reduced or switched off completely, even while the engine is running. While the vehicle is being driven, only consumer units

that are not relevant to safety

and not immediately perceptible are reduced or switched off completely, e.g.: clocking

of the heated rear window or clocking of the seat heating, reduction

of the air-conditioning blower drive by a fraction, etc.

On vehicles with diesel engines, the power consumption of the electrical auxiliary heater

is regulated.

The cutoff of individual consumer units or reduction

of the power consumption lowers the power consumption in critical situations.

This prevents the battery from discharging.

The consumer unit shutdown is only activated under 2 conditions:

- Battery charge state

in the critical range

- Alternator subjected to full load

- Control of the electrical auxiliary heater

On vehicles with diesel engines and without independent heating,

the heat exchanger for the heating system is heated additionally with

an electrical auxiliary heater based on the PTC principle.

The electrical auxiliary heater is one of the consumer units that need a relatively

high amount of power (up to 1200 W) and it is thus regulated by power management. Furthermore, another electrical auxiliary heater (600 W) is used in the rear on vehicles with rear air conditioning. These high electrical loads are regulated as follows:

- The IHKA control unit controls the electrical auxiliary heater (via LIN bus)

and the FKA control unit controls the electrical

auxiliary heater in the rear (with a pulse-width modulated signal).

- The DDE regulates the maximum electrical power output

of the electrical auxiliary heater (signal in a CAN message).

The maximum power output of the electrical auxiliary heater depends on the utilisation of the alternator as follows:

- Alternator used up to 70 %: the electrical auxiliary heater is allocated full electrical power.

- Alternator load between 70 % and

80 %: the electrical auxiliary heater may retain the power output but not increase it.

- Alternator used up to 80 %:

the electrical auxiliary heater must continuously reduce the power output

to 0 %.

- The electrical auxiliary heater regulates the heat output

of the heating register depending on the specifications of the DDE.

Energy management

The energy management monitors and controls

the energy household of the vehicle. The monitoring and control

are the result of merging various components on one circuit.

The energy management links functions or signals

and characteristic curves for the generation and output of control signals.

The following functions are described:

- Terminal control

- Data interchange in energy management

- Power supply when the vehicle is at a standstill

- Quiescent current monitoring

Terminal control

Many consumer units are connected via terminal 30g

or terminal 30g-f to the power supply.

Certain consumer units, however, are still supplied directly

by terminal 30, e.g. the anti-theft alarm system

must also be active with the ignition switched off.

Data interchange in energy management

With the engine at a standstill, certain consumer units are switched off via terminal 30g as follows: The CAS (Car Access System) switches the relay terminal 30g

off (time-controlled).

Power supply when the vehicle is at a standstill

For the power supply of the consumer units,

the following terminals are known to date:

- Terminal 30:

Continuous +

Various consumer unit are still directly connected

to terminal 30.

- Terminal R

The CAS switches terminal R.

- Terminal 15

The CAS switches terminal 15.

- Terminal 30g: Switched

continuous +

Time-dependent cutoff:

the relay terminal 30g is always present.

The relay terminal 30g

switches the connected consumer units off approx. 30 minutes after terminal R Off.

If a telephone is fitted in the vehicle, the after-run time

is extended to 60 minutes. The relay terminal 30g is activated by the Car Access System (CAS).

- Terminal 30g-f:

Deactivation in the event of a fault:

In the event of faults, the relay terminal 30g-f switches

the connected consumer units off. The relay terminal 30g-f

is controlled by the junction box electronics.

The junction box electronics (JBE) monitor

the closed-circuit current when the vehicle is at a standstill. The following faults can be detected:

- Unauthorised waking operations on the bus systems

- Control units that keep the bus systems continuously active (inhibit ”sleep”)

The following switch-off and switch-on conditions apply to the relay terminal 30g-f:

- Cutout conditions:

- Reception of the message ”Signal

off”.

After 5 minutes, relay terminal 30g-f is switched off.

- The battery status is continuously read out and evaluated in the engine control unit. If the starting capability

of the vehicle battery is insufficient, the relay is also

switched off.

- Data interchange on the buses for 10 minutes after deactivation of terminal 30g without a switch-on condition.

- Vehicle is 'wakened' 20 times after deactivation of terminal 30g without a switch-on condition.

Relay terminal 30g-f is a bi-stable relay. Each switch mode is retained even without current. Under

normal conditions, the relay is always switched on. In the event of a fault, the relay switches

the connected consumer units off.

- Switch-on conditions:

When the relay terminal 30g-f is switched off, it can only by switched on again with defined conditions required for switch-on.

Conditions required for switch-on for relay terminal 30g-f:

- Unlock vehicle

- Opening the luggage compartment lid / bonnet or door

- Switching on terminal R

Quiescent current monitoring

Closed-circuit current monitoring is necessary for a variety

of reasons.

- Maintaining starting capability

of the battery:

The energy management sends a request to cut off

the auxiliary consumer units when the starting capability of the battery

is insufficient.

The auxiliary consumer units must

deactivate their functions independent of the terminal status

and have reached their closed-circuit current after 5 minutes.

- Load deactivation

Certain consumer units may be active even though the closed-circuit current monitoring of the energy management is already running.

The consumer units are switched off according to different criteria and are divided into the following categories:

- Comfort-related consumer units

- Heated rear window (demister)

- Seat heating

The comfort-related consumer units switch off automatically after engine OFF. The switched off comfort-related consumer units can only be reactivated after a new start of the engine.

- Legally prescribed

auxiliary consumer units

- Sidelights

- Hazard warning lights

The legally prescribed auxiliary consumer units must remain operational after engine OFF as long as this is possible.

These auxiliary consumer units are not even switched off when the limit of starting capability of the battery is reached.

- Stationary consumer units

- Independent heating

- Independent ventilation

- Communication components

(displays,

terminal 30g, Telematic services)

The auxiliary consumer units listed can be switched on after engine OFF. The auxiliary consumer units switch themselves off when the limit of starting capability of the battery is reached. The cutoff is requested by the DME/DDE by means of a CAN message.

- Units with after-run due to factors inherent in the system

The units with after-run due to factors inherent in the system

can retain their function for a certain time after engine OFF.

Data interchange for the

power supply

The CAS (Car Access System) forwards the data of the terminal control

as follows:

- Terminal R ON or OFF

- Terminal 15 ON or OFF

- etc.

The CAS (Car Access System) switches the corresponding

relays for the following terminals:

The JBE (junction box electronics) switches

the corresponding relay for the following terminal:

The control units at these terminals are supplied with

voltage and ”woken up”.

The

corresponding vehicle systems are activated.

The consumer units are mainly supplied via terminal 30g and terminal 30g-f.

Certain consumer units, however, are still supplied directly

by terminal 30,

e.g. the anti-theft alarm system

must also be active with the ignition switched off.

If the battery current in the idle state of the vehicle (as of 68 minutes after terminal R Off) exceeds the value of 80 Milliamperes (mA) (can be set at the factory), a fault code memory entry is stored in the DME/DDE and a Check Control message

is displayed to the customer (increased discharge of the battery in the idle state).

If there is a suspicion of increased power consumption, a closed-circuit current measurement should be carried out without fail.

Emergency operation on failure of the bit-serial interface

If the bit-serial data interface between the engine control unit

and alternator is interrupted, the alternator voltage is regulated to a constant

14.3 Volts.

Notes for Service department

General information

The following general data is provided:

- Trickle charge for

the battery

- Protection of the intelligent battery sensor

- Battery replacement

- Alternator

Trickle charge for

the battery

Note! Do not connect the trickle charger to the lighter.

The lighter is supplied with voltage by the distribution box in the junction box across a relay. After terminal 15 OFF, this relay de-energises.

This means that a trickle charger connected at the lighter would be disconnected from the battery. Only charge the battery via the starting-aid terminal. This is the only way the energy supply can be registered by the vehicle.

Protection of the intelligent battery sensor

CAUTION! Risk of destruction if subjected to mechanical stress.

- Do not attach any additional

connections to the negative terminal of the battery.

- Do not modify the ground cable.

The

ground cable also carries off heat.

- Do not set up a connection between the IBS (intelligent

battery sensor) and the sensor screw.

- When disconnecting the pole piece from the battery terminal,

do not use force:

- Do not pull on the ground cable.

- Do not apply any tool under the IBS to lever out the pole piece.

- Do not use connections of the IBS as levers.

- Use a torque wrench and

set the tightening torque in accordance with repair instructions.

- Do not slacken or tighten the sensor screw (Torx screw).

- Avoid contact between the IBS and earth.

Battery replacement

CAUTION! Risk of destroying the IBS and cables when replacing the battery.

When replacing the battery, the IBS (intelligent

battery sensor) and cables can be destroyed due to mechanical stress.

When replacing the battery, observe the following:

- Always proceed in accordance with repair instructions.

- Avoid mechanical stress of the integrated

battery sensor.

Note! On replacing the battery, run the service function ”Register battery replacement”.

On replacing the battery, use the battery size (capacity) fitted as series standard.

The battery size required for the vehicle is coded in the Car Access System (CAS) and in the engine electronics (DME/DDE).

- If a battery

with a different capacity is fitted, recode the CAS. Run retrofit ”Battery” with

Progman.

- Delete fault code memory entries with reference to the replacing the battery in the engine control unit.

Alternator

The alternator model fitted depends on the

engine used and the vehicle equipment.

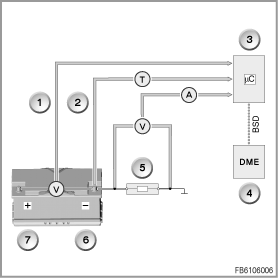

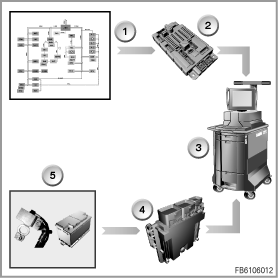

Diagnosis instruction

Energy diagnosis

A breakdown due to a flat battery or problems

in the vehicle electrical system can have wide variety of causes. In most cases,

the cause does not lie with the battery itself. For this reason, replacing the battery will only rarely provide a sustained solution to the problem.

Instead, a systematic

diagnosis of the source of the fault is necessary.

Faults

are often no longer present when the vehicle comes to the workshop. This is why data stored in the vehicle is the basis

for diagnosis. Information on the battery status as well as functional processes in the various

bus systems are stored in the corresponding control units.

This information can be called up and evaluated by the BMW diagnosis system. The BMW diagnosis system has a test module for this. The test module for energy diagnosis

reads all the relevant data from the corresponding control units.

Index

|

Explanation

|

Index

|

Explanation

|

1

|

Vehicle network with control units

|

2

|

Junction box electronics

(JBE)

|

3

|

BMW diagnosis system

|

4

|

DME (Digital Engine Electronics) or DDE (Digital Diesel Electronics)

|

5

|

Intelligent battery sensor (IBS)

at the negative battery terminal

|

|

|

The following information is displayed:

- Conspicuous information

An entry is only made when a fault is presumed.

- Standard information

This information

can always be displayed.

The energy detects the following faults:

- Operating errors

- Fault on the vehicle

- Operating errors

- Sidelights, parking lights or hazard warning lights were switched on for too long with the vehicle parked.

- Terminal R or terminal 15 were switched on for too long while the engine was off.

- Immobilisation period of the vehicle was too long.

- Frequent short distance driving with a number of

current consumer units switched on

- Fault on the vehicle

- Battery defective

- Alternator defective

- Excessive closed-circuit current, at times greater than 80 Milliampere

(mA) with inactive bus systems

- Vehicle does not ”go to sleep”: the vehicle

does not reach the idle state; the bus systems remain active.

- Vehicle keeps being woken up

Notes on coding / programming

The data of the battery is coded in the Car Access System (CAS). The data can be read out using the BMW diagnosis system.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature