The automatic gearbox is controlled by the mechatronics module. The mechatronics module is a combination of a hydraulic control unit (hydraulic selector unit) and an electronics module.

The hydraulic control unit is the hydraulic part of the gearbox control.

The electronics module contains the EGS control unit, the sensors as well as the gearbox-internal connections.

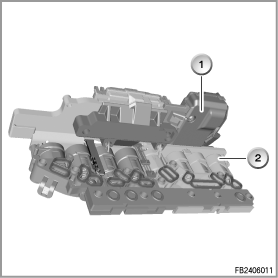

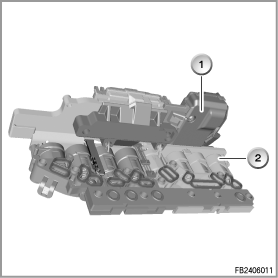

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Electronic module |

2 |

Hydraulic control unit (hydraulic selector unit) |

The following components of the mechatronics module are described:

The EGS control unit controls gearshift points, the shift quality, engaging and disengaging the converter lockup clutch as well as the hydraulic pressure.

The data the EGS control unit requires to shift the gears is transferred on the Powertrain CAN (PT-CAN) to the EGS control unit (e.g. fuel injection period, engine speed, throttle-valve angle, engine temperature and engine intervention). In the mechatronics module, the EGS control unit directly activates the solenoid valves and the electronic pressure control valves.

The clutches of the automatic gearbox are hydraulically controlled in the hydraulic control unit.

For gearbox control, the following components are installed in the hydraulic control unit:

The following system functions are described:

In the same way as the automatic gearboxes used to date, this 6-speed-automatic gearbox also offers a choice between a comfort program and sport program.

The adaptive gearbox control (component of the Electronic Gearbox Control) adapts the shift characteristics of the comfort program and sport program to the driver's choice and the driving situation.

In each of the two programs, the adaptive gearbox control switches on request from a basic characteristic map into a performance-oriented characteristic map:

The adaptive gearbox control takes account of the following requirements:

Adaptation to the driver type

The adaptation to the driver type runs via the following values:

The adaptation to the driver type is restarted every time the vehicle drives off from a standstill.

Hill ascent and operation with trailer

This function is based on a comparison of the actual car acceleration with a nominal value. Taking account of the current operating condition of the engine, the acceleration on a trip with normal load on a float road is estimated. If the actual acceleration is significantly below the theoretical value, the function ”Hill ascent and operation with trailer” becomes active.

The configuration of the corresponding shift characteristic maps permit a driving style with high revolutions. Unwanted upshifts and frequently upshifts and downshifts are excluded or severely limited.

Hill descent

When the EGS control unit detects a hill descent, it shifts to the next-lowest gear if the driving speed increases. This reinforces the brake effect of the engine. A downshift only takes place if the engine speed lies below the maximum number of revolutions of the next-lowest gear.

The EGS control unit detects the hill descent by the signals from the throttle valve potentiometer (load), from the wheel-speed sensors (driving speed) and from the brake-light switch (brake operation).

Braking deceleration and automatic upshift

To brake the vehicle, the driver takes his or her foot from the accelerator pedal and operates the brake if required. According to the characteristic curve, closure of the throttle would trigger an upshift. These gear changes make no sense in conjunction with braking, as they prevent use of the engine braking effect.

The braking intention can frequently be recognised by a very rapid return of the driving pedal to the zero position. When such an action is detected, an upshift is suppressed until the accelerator pedal is in the zero position and the vehicle is coasting.

Winter program (only in selector-lever position ”D”)

If the drive wheels slip even at low acceleration, the winter program is activated automatically. The winter program ensures better traction by eliminating 1st gear. Early upshifts reduce the reaction on load change. If the wheels do not slip with high input torque for a number of seconds, the winter program is deactivated again.

The overlap control ensures gentle shift characteristics as follows: in the overlap control, a number of multi-plate clutches are used simultaneously. In the engaged multi-plate clutch, the pressure is reduced and simultaneously pressure is built up in the clutch to be engaged. The pressure decrease or pressure build-up is maintained until a synchronised speed is reached. Then, the hydraulic pressure for the multi-plate clutch to be engaged can be built up in full. The overlap control is in all shifts from 1st to 6th gear and from 6th to 1st gear.

It is only possible to start the engine in selector-lever position ”P” or ”N”.

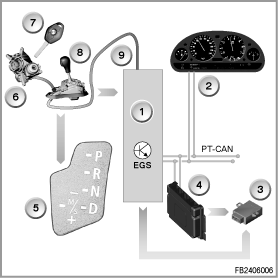

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

EGS control unit integrated in the mechatronics module |

2 |

Instrument cluster (KOMBI) |

3 |

Electronic immobiliser (EWS) |

4 |

Digital Engine Electronics (DME) |

5 |

Display of the selector-lever position with gearshift diagram in the selector-lever cover |

6 |

Bowden cable for withdrawal lock of the ignition lock |

7 |

Ignition lock with withdrawal lock (interlock) |

8 |

Selector lever |

9 |

Bowden cable for gear position switch with gearbox position sensor and parking lock |

PT-CAN |

Powertrain CAN |

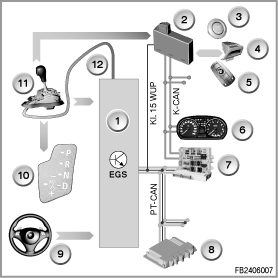

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

EGS control unit integrated in the mechatronics module |

2 |

Car Access System (CAS) |

3 |

START-STOP button |

4 |

Insert compartment with withdrawal lock (interlock) |

5 |

Remote control |

6 |

Instrument cluster (KOMBI) |

7 |

Junction box electronics (JBE) |

8 |

DME (Digital Engine Electronics) or DDE (Digital Diesel Electronics) |

9 |

Steering wheel with rocker switches |

10 |

Display of the selector-lever position with gearshift diagram in the selector-lever cover |

11 |

Selector lever |

12 |

Bowden cable for gear position switch with gearbox position sensor and parking lock |

K CAN |

Body CAN |

Terminal 15 WUP |

Wake-up line (terminal 15 wake up) |

PT-CAN |

Powertrain CAN |

|

|

After every engine start below a certain engine temperature, the warm-up program is started. In the warm-up program, the automatic gearbox remains in the performance-oriented characteristic map XE or XS until a certain temperature is reached. The gears are only shifted at higher engine speeds. This enables the engine and catalytic converter to reach their operating temperature more quickly.

Up to a certain gearbox oil temperature, the converter lockup clutch is not regulated or closed.

During the shifting operation, the EGS control unit sends signals that influence the DME (Digital Engine Electronics) or DDE (Digital Diesel Electronics).

The DME sets back the ignition timing angle for a few milliseconds.

The DDE reduces the volume of fuel for a few milliseconds by shortening the fuel injection period.

These measures briefly reduce the engine torque, improve shift quality, reduce the load on the gearbox, and shorten the shifting time.

A gearshift lock prevents shifting into a lower gear until the engine speed lies below the maximum number of revolutions of the next-lowest gear. The engine-speed signal is transferred by the DME/DDE to the EGS control unit.

The gearshift lock prevents damage to the engine and gearbox.

The electronically controlled reverse gear interlock blocks the engagement of reverse gear at forward driving speeds above 8 kph. If the specified driving speed is exceeded, the corresponding solenoid valves are not activated. This prevents filling the multi-plate clutches for reverse gear.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature