The following components belong to the common rail system and influence the rail pressure control:

It goes without saying that the fuel supply of the high-pressure system also has a major influence on the rail pressure control. If the presupply control does not work perfectly, perfect function of the rail pressure control is not possible!

Depending on the engine variant, variations of the components are deployed, see the following table:

Engine |

DRV |

HDP |

Fuel injectors |

N47uL |

DRV2U |

CP4.1 |

Solenoid valve |

N47oL |

DRV3.2 |

CP4.1 |

Piezo |

N47TOP |

DRV3.3 |

CP4.1H |

Piezo |

The high pressure pump constantly generates the system pressure held in the fuel rail. Two actuators are used to regulate the right rail pressure (dual-actuator concept):

The fuel-rail pressure is adjusted to the correct level according to engine operating parameters by one of the following three possible control methods:

The two control methods are used under the following engine operating conditions:

Depending on the engine variant, various maximum rail pressures are used, see the following table:

Engine |

Maximum rail pressure |

N47uL |

1600 bar |

N47oL |

1800 bar |

N47TOP |

2000 bar |

The rail pressure is monitored during engine start and engine operation by way of setpoint/actual value comparison. The rail pressure sensor supplies the actual value to the DDE. The target value is calculated by the DDE depending on the operating status. If the DDE detects a discrepancy between the target value and actual level that is outside the permissible limits, a fault is stored in the fault memory.

An impermissible deviation of the rail pressure from the target value can be caused by the following:

If the DDE detects a rail-pressure control discrepancy that is outside the permissible limits, its first action is to limit the fuel injection rate. If this does not eliminate the control deviation or keep it to a low level, the engine cuts out if the rail pressure is too low. If rail pressure that is too low is detected at engine start, the engine start is not possible.

The high-pressure pump CP4.1 is a radial piston pump with one cylinder. The shaft of the high-pressure pump has two cams that operate the pistons.

The high-pressure pump is driven via the chain drive of the engine. As the chain drive is located at the back of the engine, the high-pressure pump is also mounted at the back of the engine.

The rail-pressure sensor registers the fuel pressure in the rail and serves as a sensor for rail pressure control and volume metering. The rail pressure sensor is mounted on the front end of the rail.

The DDE control unit supplies the rail-pressure sensor with earth and a supply voltage of 5 V.

The rail pressure goes through a bore hole in the sensor to a membrane with a sensor element. The deformation of the membrane is converted via the sensor element into an electrical voltage and output at the DDE. The voltage signal increases with increasing rail pressure in linear form. The adaptation of the rail-pressure sensor is implemented via the application of various characteristic curves.

Troubleshooting

If the DDE detects a fault on the rail-pressure sensor, the DDE issues a substitute value and limits the fuel injection rate.

The rail pressure control valve is designed as an electrically operated valve that is mounted at the rear end of the rail.

When rail pressure control is active, the DDE activates the rail pressure control valve by means of a variable pulse duty factor in order to set the rail pressure to the level calculated by the DDE. The fuel that is taken off is fed by the rail-pressure regulating valve into the return line.

Depending on the type of activation, the pressure control valve allows more or less fuel to flow from the high pressure side into the virtually depressurized return line. The more fuel flows into the return flow the lower the pressure build-up on the high-pressure side.

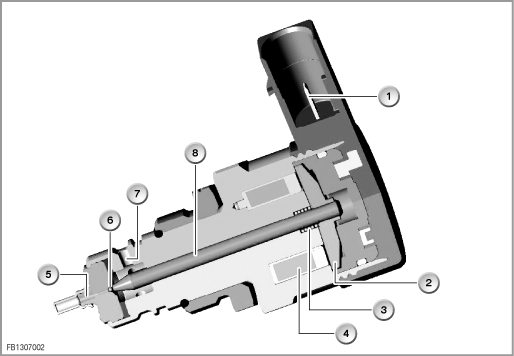

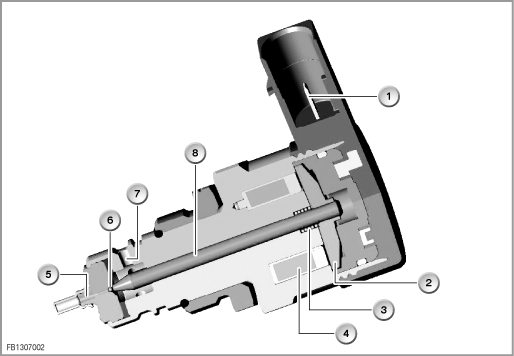

Fig. 1: sectional view DRV3.2

1 |

Plug-in contact |

5 |

Bore hole towards the high-pressure side |

2 |

Armature plate |

6 |

Ball valve |

3 |

Opening spring |

7 |

Bore hole towards the return flow side |

4 |

Coil for electromagnet |

8 |

Pressure pin |

Activation of the rail-pressure regulating valve means that the coil is supplied with current. This energises the armature plate and the pressure pin presses the valve ball into the valve seat. The stronger the valve ball is pressed into the valve seat, the less fuel can flow into the return flow.

The relationships between pulse duty factor, activating current, pressure build-up and volumetric flow can be seen from the following table:

Pulse duty factor |

Control signal current |

Pressure build-up |

Volumetric flow into return line |

High |

High |

High |

Low |

Low |

Low |

Low |

High |

When the rail-pressure regulating valve is not supplied with current, the valve is opened. This means that the rail pressure is reduced to zero.

On account of the different maximum rail pressures in the N47 variants, various rail-pressure regulating valve variants are fitted, see the following table:

Engine |

Rail-pressure regulating valve |

Maximum rail pressure |

N47uL |

DRV2U |

1600 bar |

N47oL |

DRV3.2 |

1800 bar |

N47TOP |

DRV3.3 |

2000 bar |

As a general principle, the operating principle of the rail-pressure regulating valve variants is the same; the variants only differ with regard to structure for adaptation to the pressures.

Troubleshooting

If activation of the rail-pressure regulating valve is interrupted or there is a short circuit to earth, the engine shuts down.

If the DDE detects a short circuit to positive, the DDE and limits the fuel injection rate and switched to injection-rate control.

The flow regulating valve is an electrically controlled valve that is mounted on the high pressure pump. When volumetric flow regulation is active, the DDE controls the flow regulating valve by means of a variable pulse duty factor in order to set the rail pressure to the level calculated by the DDE.

The flow regulating valve controls the flow of fuel into the high pressure pump from the low-pressure side, thereby controlling fuel-rail pressure as required. The less fuel the flow regulating valve allows to flow into the high pressure side, the less the radial cylinder of the high-pressure pump is filled. The consequence is that less rail pressure is built up.

Pulse duty factor, control signal current, rail pressure and volumetric flow through the valve are related to one another as follows:

Pulse duty factor |

Control signal current |

Pressure build-up |

Volumetric flow into high-pressure side |

High |

High |

Low |

Low |

Low |

Low |

High |

High |

Troubleshooting

If activation of the flow regulating valve is interrupted or has a short circuit to earth, the flow regulating valve switches to full delivery. The DDE detects the fault, limits the fuel injection rate and switches to pressure regulation.

In the event of a short circuit to positive, the engine shuts down.

Depending on the engine variant, solenoid valve or Piezo injectors are used, see the following table:

Engine |

Fuel injectors |

N47uL |

Solenoid valve |

N47oL |

Piezo |

N47TOP |

Piezo |

Independently of the fuel injector variant, the fuel delivery pressure present in the rail is continously applied to the injectors. Fuel is injected into the combustion chambers upon electrical activation by the DDE control unit.

Electrical control

The wires of the high side P_MVH (solenoid valve) or P_PIH (Piezo) are bridged internally in the DDE control unit, but each injector is connected to the DDE control unit via its own pin and a wire.

Important!

If a fault occurs on the high side, the fact that the wires are combined means that the cause of the fault may originate from any of the wires. In such cases, all injectors will fail.

Troubleshooting on solenoid valve injectors

The following possibilities are available for a complete diagnosis of the solenoid valve injectors:

Troubleshooting on Piezo injectors

The following possibilities are available for a complete diagnosis of the Piezo injectors:

It is currently not possible to measure the return volume for Piezo injectors. Due to the way Piezo injectors are designed and how they function, the return volume is considerably lower than in the case of solenoid valve injectors.

Important!

On engine with Piezo injectors, the pre-delivery pressure is applied in the fuel return flow! This is necessary for operation of the Piezo injectors.

Replacing the high-pressure pump

If the high-pressure pump is replaced, the adaptation of the electrical fuel pump must be reset, see corresponding service function.

Replacing injectors

If one or more injectors is replaced, the injector quantity adjustment must be carried out, see corresponding service function.

Replacing the rail-pressure regulating valve

If the rail-pressure regulating valve is replaced, the adaptation of the rail-pressure regulating valve must be reset, see corresponding service function.