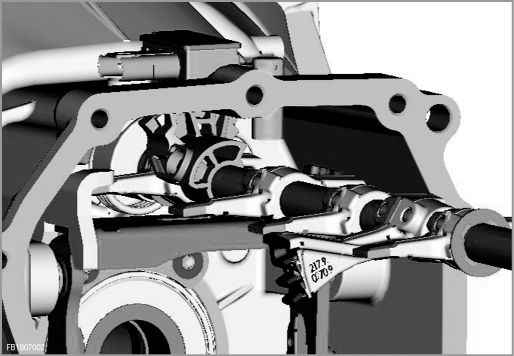

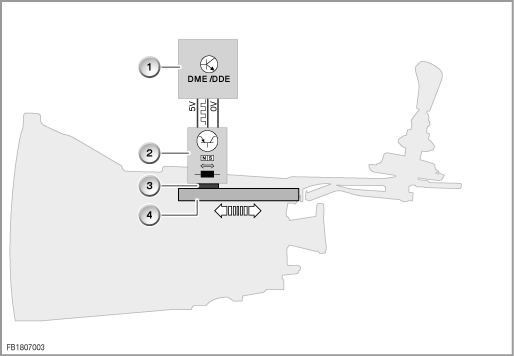

On vehicles with manual gearboxes, the zero gear sensor is fitted on the transmission case. The zero gear sensor is a PLCD sensor, which means the sensor detects a linear change in the location (excursion) without contact on the basis of changes with regard to the magnetic state. The gearshift operation shifts the selector rod (4) and thus the magnet in the gearbox. The PLCD sensor enables the engine management system to detect the position of the gearstick. The following illustrations show the schema of the assembly and sectional views of the sensor attached to the gearbox:

The following part designations apply:

So that the engine management system knows the ”zero position” of the gear selector switch / gearstick, it is necessary to be able to learn this position in the vehicle. This learning routine takes place for the most part automatically in the plants and is possible using the DIS tester in cases of repair. To run this, run the service function <Learn / write zero gear sensor>.

The zero position of the gearstick is normally approx. 50 % (+/- tolerance).

Note:

Incorrectly learned values of the zero position lead to problems with regard to the availability of the automatic engine start-stop function and deficiencies with regard to reproducibility of the system characteristics of all MSA-specific parameters!