The Tyre Pressure Monitor (TPM) is a system for monitoring the tyre inflation pressure while the vehicle is being driven. To achieve this, the tyre inflation pressure and tyre air temperature are measured at certain intervals at the request of the TPM control unit and telemetrically transmitted across an HF transmission path to the TPM aerial. The TPM aerial feeds the signals back across the bus to the TPM control unit. The control unit evaluates the received data. If required, it forwards the information to the driver. The driver is thus informed of a necessary correction of tyre inflation pressure or a puncture that might have occurred.

The following components are described for the TPM:

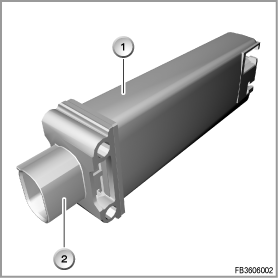

The TPM aerial is generally located on the underbody. Depending on the model series, the position can be in the front area (cross-member of A-pillar) or in the central area of the underbody.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

TPM aerial |

2 |

Connector for TPM aerial |

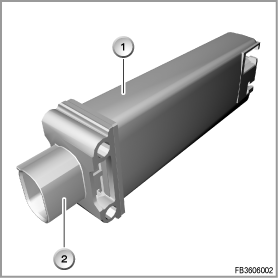

The 4 TPM transmitters are fitted under the wheel arch trim in the wheelhouses. The TPM transmitters send the requests from the control unit to the wheel electronics systems. This achieves bidirectional communication.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Connector for TPM transmitter |

2 |

TPM transmitters |

The wheel electronic systems are mounted in the wheel drop centre. Together with the filling valve, they form a compact unit and are fitted in the same way as a screw valve in the rim. The wheel electronics system contains:

The wheel electronics system is activated on initial fill of the tyre. The measured values are transmitted from the wheel electronics system either on request or cyclically (every 3 seconds) from the tyre to the TPM aerial. This cycle is temporarily shortened if a certain pressure change is detected. In the case of temperature values greater than 120 °C inside the tyre, the wheel electronic system is switched off; if it cools down to less than 110 °C, it is switched on again.

Transmission rate normal: 54 s

Transmission rate increased: 0.8 s

Battery service life: approx. 10 years.

The TPM control unit evaluates the transmitted pressure and temperature values from the individual tyres. If required, a Check Control message in the instrument cluster notifies the driver. This signal may also be supported by supplementary information via the Control Display.

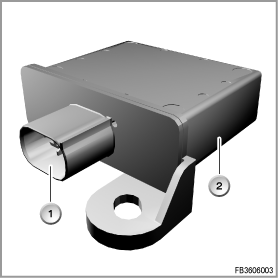

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

TPM control unit |

2 |

Connector for TPM control unit |

The following system functions are described for the TPM:

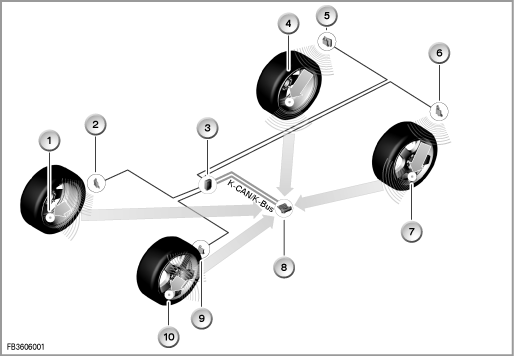

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Wheel electronics system, front right |

2 |

TPM transmitter, front right |

3 |

TPM control unit |

4 |

Wheel electronics system, rear right |

5 |

TPM transmitter, rear right |

6 |

TPM transmitter, rear left |

7 |

Wheel electronics system, rear left |

8 |

TPM aerial |

9 |

TPM transmitter, front left |

10 |

Wheel electronics system, front left |

The TPM monitors the tyre inflation pressure while the vehicle is being driven. The tyre pressure to be monitored is specified by the driver. Using the control function in the iDrive or the TPM button, the driver instructs the system to adopt the current tyre pressure as setpoint pressure (reset). The plausibility of the setpoint pressure is checked before the TPM control unit adopts it (axle-wise comparison of the specified pressures, minimum pressures). A reset is only possible when the tyre inflation pressure on all wheels is at least 1.6 bar. If the tyre pressure of one wheel falls below this limit, a Check Control message is issued immediately. If the pressure difference between the wheels on one axle > 0.4 bar, the reset is rejected following a plausibility check. A Check Control message is output. Remedy: set tyre pressures to the correct values and then run the reset once again.

Internal sequence after triggered adaptation process (reset):

On comparison of the current tyre pressure with the specified pressure, the air temperature is taken into account. On the basis of the specified pressure and temperature during the reset, the TPM calculates the limit values for the tyre inflation pressure for the current air temperature. The tyre inflation pressure increases by 0.1 bar per 10 °C increase in temperature. If the temperature-evaluated values are not reached, the TPM issues a Check Control message.

In the case of vehicles without iDrive, the TPM is reset using a button in the centre console switch centre. This TPM button must be pressed for 4 seconds. On vehicles with iDrive, the TPM is reset via the menu item: Settings/Vehicle/TPM/Reset. In general, the reset can be carried out with the ignition on or engine on (only when vehicle is stationary).

Important! Conditions for reset.

The TPM must be reset in the following cases:

Note! Check of the wheel electronics system

A check as to whether the correct wheel electronics system has been fitted can only by run after the tyre has been removed. Unfortunately, a query via the BMW diagnosis system is not possible for technical reasons.

Note! Reset of the TPM control unit

During the reset, the control unit functions (measurement data of wheels 1 - 5) contain substitute values until the wheel allocation is complete (e.g. 6.4 bar; 127 °Celsius). To enable successful conclusion of the wheel allocation, the wheels must turn.

Transmission frequency of the system: 433 MHz

Reception frequency of the system: 125 MHz

No liability can be accepted for printing or other errors. Subject to changes of a technical nature