Stratified-charge operation (lean mixture) is described using the N53 6-cylinder engine as an example. The new N43 4-cylinder petrol engine also has stratified-charge operation.

The basis of construction for the N53 (e.g. N53B30O0) is the N52. In the same way as the N54, the N53 has direct fuel injection. However, the N53 is not charged. Moreover, the N53 is operated with stratified charge (lambda value up to 2.5) in wide operating ranges. The 6-cylinder engine has been developed for the European market (ACEA: Association of European Automobile Manufacturers). The exhaust system has a nitrogen oxide catalytic converter.

The beamed direct fuel injection (HPI: High Precision Injection) delivers additional levels of autonomy:

This enables a positive influence on the power output, engine torque, consumption and pollutant emissions.

With stratified-charge operation, efficient dynamics (BMW marketing term: EfficientDynamics) reach a new level. The engine develops its performance potential with reduced fuel consumption.

The following components are described:

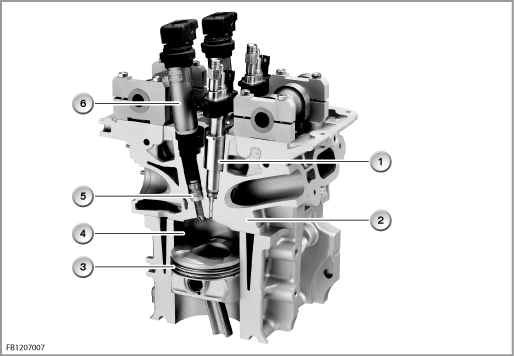

In the case of direct fuel injection, the injector is located centrally between the valves and in the immediate vicinity of the spark plug. In this position, the injector, which opens outwardly, can distribute the fuel in a ring (hollow cone) and very evenly in the combustion chamber. This enables not only more exact mixture metering, but at the same time a cooling effect. This permits greater compression and thus optimises the efficiency of the combustion process.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Injectors |

2 |

Cylinder head |

3 |

Pistons |

4 |

Combustion chamber |

5 |

Spark plug |

6 |

Ignition coil |

The injector sprays the fuel into the combustion chamber under high pressure. The injector opens the tip of the nozzle needle outwards and forms a ring gap that is up to 40 micrometres wide. The ring gap shapes the beamed direct fuel injection and ensures even divergence through a hollow cone. The piezo-electric activation has the following advantages compared to activation via solenoid coils:

This results in significant improvements with regard to pollutant emission as well as fuel consumption.

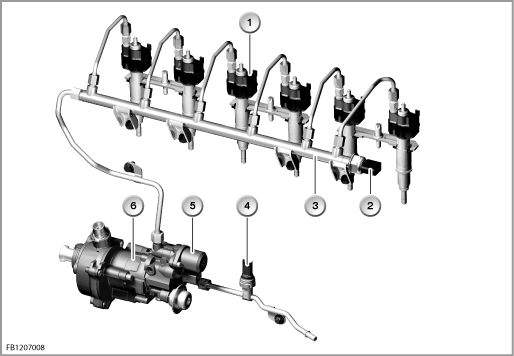

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Injectors |

2 |

Rail pressure sensor |

3 |

Rail |

4 |

Fuel low pressure sensor |

5 |

Flow regulating valve |

6 |

High-pressure pump |

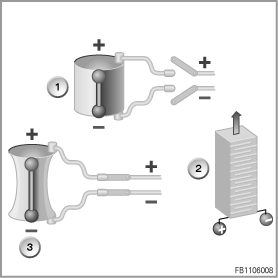

A piezo element is an electromechanical converter. The piezo element is a type of ceramic that converts electrical energy directly into mechanical energy (power/travel). The piezo element expands when voltage is applied. This creates the lift of the nozzle needle. To achieve a greater lift, a piezo element can be structured in a number of layers.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Piezo element without voltage |

2 |

Layers of piezo elements |

3 |

Piezo element, voltage applied |

|

|

Nitrogen oxide is the generic term for the various compound of nitrogen and oxygen. Nitrogen oxides form as a consequence of secondary reactions in all combustion processes with air, which contains nitrogen. The nitrogen is not involved in the actual combustion of the carbon. The temperatures and pressure that occur in the combustion chamber, however, lead to oxidation reactions with oxygen in the air. This creates mainly nitrogen monoxide (NO) and nitrogen dioxide (NO2) as well as to a minor degree di-nitrogen oxide (N2O).

The higher the temperatures are and the more air is in the combustion mixture, the greater the proportion of nitrogen oxide that forms. This is why engines with stratified-charge operation must be equipped with a nitrogen oxide catalytic converter.

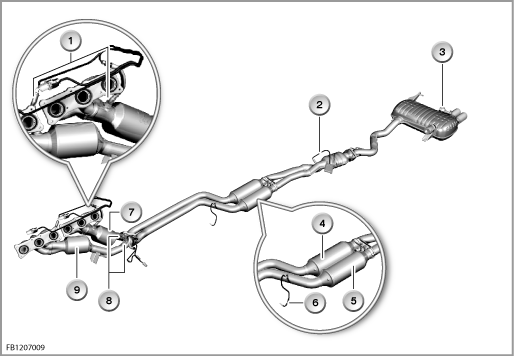

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Oxygen sensors (control sensors) |

2 |

Nitrogen oxide sensor |

3 |

Exhaust flap |

4 |

Nitrogen oxide catalytic converter, cylinder bank 2 |

5 |

Nitrogen oxide catalytic converter, cylinder bank 1 |

6 |

Exhaust gas temperature sensor |

7 |

3-way catalytic converter, cylinder bank 2 |

8 |

Oxygen sensors (control sensors) |

9 |

3-way catalytic converter, cylinder bank 1 |

|

|

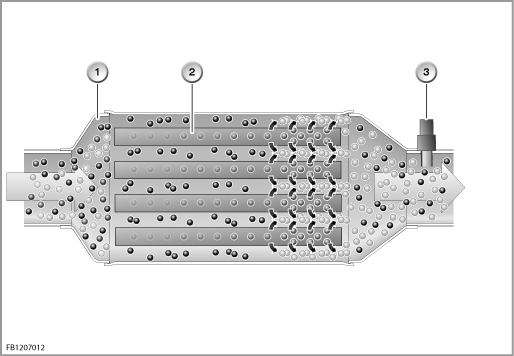

The structure of the nitrogen oxide catalytic converter is similar to that of a 3-way catalytic converter. A precious metal with catalytic effect and a material for intermediate storage of the nitrogen oxides are applied to a substrate. The nitrogen oxide catalytic converter works in a temperature range of 220 °C to 450 °C. In this temperature range, it is possible to store and regenerate nitrogen oxides. For desulphurisation, an even higher temperature range of 600 °C to 650 °C is required. These temperature ranges are monitored by the exhaust gas temperature sensor. The engine management system (MSD80) controls and monitors the regeneration. To do so, the engine management system uses a calculation model and the measured values of the nitrogen oxide sensor.

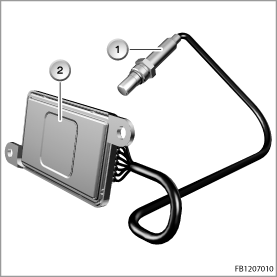

The nitrogen oxide sensor consists of the measuring sensor itself and an associated electronic evaluation unit. The electronic evaluation unit communicates across the Local-CAN (local CAN bus) with the engine control unit.

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Nitrogen oxide sensor |

2 |

Electronic evaluator |

The operating principle of the nitrogen oxide sensor is comparable to that of a broadband oxygen sensor. However, it measures nitrogen oxide. The measurement procedure is based on deriving the actual nitrogen oxide measurement from an oxygen measurement. The nitrogen oxide sensor is inseparably connected to the electronic evaluation unit.

The following system functions are described:

Note! Explanation of the term stratified charge.

Stratified charge is a process for petrol engines. Fuel is injected in such a way that in the area the spark plug an ignitable mixture (lambda value = 0.5 to 1.0) is created. The remaining combustion chamber has a very lean, non-ignitable mixture (lambda value = 1.5 to 2.5).

With direct fuel injection, the injector flows directly into the combustion chamber. The combustion air is taken in virtually unthrottled (via the throttle valve). The fuel is only injected at an advanced stage, during the compression stroke. A ring of ignitable mixture is only created in the area of the spark plug. The main part of the combustion chamber is filled with air and residual gases. The air surplus leads to a composition of emissions where no reduction in the nitrogen oxides in the exhaust gas is possible with a conventional 3-way catalytic converter. This is why a nitrogen oxide catalytic converter is required.

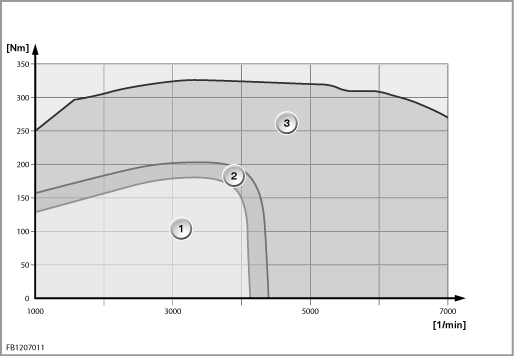

Operation with stratified charge is not possible across the entire operating range of an engine. The following physical limit ranges result:

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Extended stratified-charge operation: |

2 |

Transition range: |

3 |

Homogeneous operating range: |

|

|

The storage capacity of the nitrogen oxide catalytic converter is limited. When the storage material is completely saturated, no more nitrogen oxide can be absorbed. The engine management system detects this saturation as follows:

Index |

Explanation |

Index |

Explanation |

|---|---|---|---|

1 |

Nitrogen oxide catalytic converter |

2 |

Storage material (barium) |

3 |

Nitrogen oxide sensor |

|

|

When a maximum storage volume of the storage catalytic converter is determined, the engine management system initiates the regeneration of the nitrogen oxides. To do so, the mixture is slightly enriched (lambda value = 0.8). During the regeneration the nitrogen oxides on the catalytic converter are converted. After the conversion, the enriched engine operation is terminated again. Her, too, a calculation model and the nitrogen oxide sensor are used. The nitrogen oxide sensor measures the oxygen concentration in the exhaust gas. A voltage jump from ”lean” to ”rich” indicates when the regeneration has been completed.

Important: Fuel high pressure system!

Work on this fuel system is only permitted after the engine has cooled. The coolant temperature must not exceed 40 °C. Otherwise there is a risk of injury due to the residual pressure in the fuel high pressure system.

Note: Comply with repair instructions.

When working on the fuel high pressure system, pay particular attention to cleanliness. Even the smallest impurities and damage to the bolt connections of the high pressure lines can lead to leaks.

Note: Emergency program.

In the event of implausible exhaust emissions, the emergency program is started. In addition, the engine is operated with a homogeneous mixture.

There are 2 emergency programs: emergency program with 5 bar injection pressure and emergency program with 100 bar injection pressure.

Possible causes of the emergency program with 5 bar:

Possible causes of the emergency program with 100 bar:

Note: Service function 'Adjustment of injector'.

If the engine control unit or an injector is replaced, the printed code of each injector must be allocated to the right cylinder in the engine control unit. Run the service function ”Injector adjustment” on the BMW diagnosis system.

Note: Service functions 'nitrogen oxide catalytic converter'.

If the engine control unit is replaced, the ageing and level of sulphurisation of the nitrogen oxide catalytic converters must be transferred.

If the nitrogen oxide catalytic converters are replaced, the ageing and level of sulphurisation must be initialised.

Note: Sulphurisation of the nitrogen oxide catalytic converter.

Non-sulphur fuel contains a minimum of sulphur. The sulphur reduces the storage capacity of the nitrogen oxide catalytic converter. Sulphurisation of the nitrogen oxide catalytic converter means that the engine is only operated with homogeneous mixture, as no nitrogen oxides can be absorbed. The engine management system detects the sulphurisation of the nitrogen oxide catalytic converter. For desulphurisation, the nitrogen oxide catalytic converter is heated to 600 °C to 650 °C and operated with a rich mixture (lambda value = 0.94).

The following vehicle operation is necessary to actively heat up the nitrogen oxide catalytic converter:

In the event of a fault code memory entry (NOx catalytic converter sulphurised), more frequent heating-up can be activated using a service function. This enabling remains active until the nitrogen oxide catalytic converter has been successfully desulphurised.

No liability can be accepted for printing or other errors. Subject to changes of a technical nature