A whistling noise can be heard from the ventilation system.

The noise occurs above all under the following conditions:

The blower must be examined to determine traces of water and rust, also in the area of the lower thrust bearing.

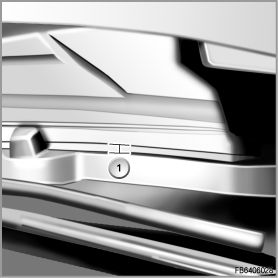

To do so, open the blower cap and blower head. See Fig 1.

If the blower is corroded, it must be replaced.

If water entry is determined, the area of the cover for the cowl must be checked for leak-tightness. If necessary, the sealing strip for the cross-member and retaining strip for the cover for the cowl are to be replaced.

Refer to the following repair instructions:

- RA 5113117 Replacing the cover for the cowl

- RA 5131... Fitting / replacing the retaining strip for the cover of the cowl

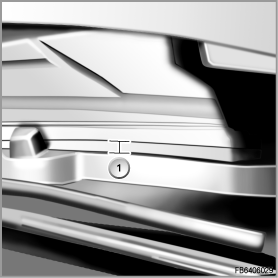

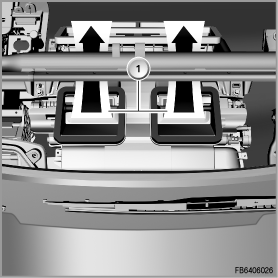

It must also be checked whether the upper part of the microfilter housing is correctly mounted. Under certain circumstances, tension can occur in the upper part in assembly, resulting in leaks. See Fig. 2 and Fig. 3.

The illustrations show the microfilter housing from the vehicle interior (through the windscreen).

Fig. 2 shows a correctly bolted upper part. Fig. 3 shows an upper part bolted with tension. If necessary, the bolt connection must be slackened, the upper part realigned and correctly bolted again. See also RA 6431081.

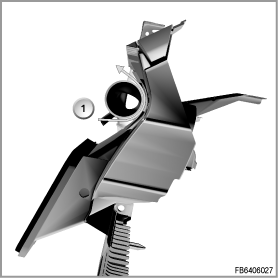

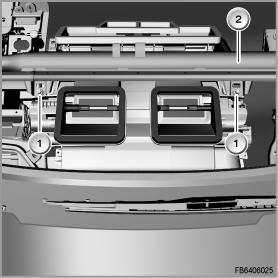

If no water entry is determined, it must be checked whether there is a collision between the support tube of the dashboard and the heater/air conditioner. To do so, the dashboard must be removed. Use a sheet of paper to check the ease-of-movement of the heater/air conditioner in relation to the support tube in the area between the fresh-air flaps and the defrost flaps. It must be possible to push the sheet of paper between the heater/air conditioner and support tube without difficulty. See Fig. 4 and Fig. 5.

If the sheet of paper cannot be pushed through and the heater/air conditioner strikes the support tube, a shim (8 x 23 x 1 mm) must be fitted at the two fastening points. Then check the ease-of-movement once again. See Fig 6.

If the ease-of-movement was established, fully heat up the heater/air conditioner by operating it for 60 minutes at a set temperature of at least 26 °C (78.8 °F). It must then be checked whether the whistling noise still occurs. If the whistling noise still occurs, a new empty housing for the heater/air conditioner must be fitted. After fitting the new empty housing, the ease-of-movement in relation to the support tube must be checked again and, if applicable, ensured by inserting shims.

After fitting the new empty housing, the ease-of-movement in relation to the support tube must be checked again and, if applicable, ensured by inserting shims.

Check blower for corrosion.

If the gap (1) is less than 1 cm, the upper part is correctly fitted.

If the gap (1) is 1.5 cm, the upper part has been fitted with tension.

(1) Sheet of paper

(1) Sheet of paper

(1) Fastening points

(2) Support tube