The fuel supply on the N47 4-cylinder diesel engine is ensured by a pressure-controlled system.

The following components of the fuel supply system are described:

The function of the fuel presupply control is integrated in the DDE control module. The DDE uses the fuel pressure-temperature sensor to determine the current actual pressure in the presupply system. The DDE uses a number of input variables to determine the adjusting value signal factor to regulate the pre-delivery pressure. The pre-delivery pressure is regulated to a pressure of 4.8 - 5.0 bar.

The input variables relevant to determining the adjusting value are:

The adjusting value is sent to the fuel pump control in the form of a CAN message. The adjusting value is sent in the unit l/h. The value range is 0 - 254 l/h.

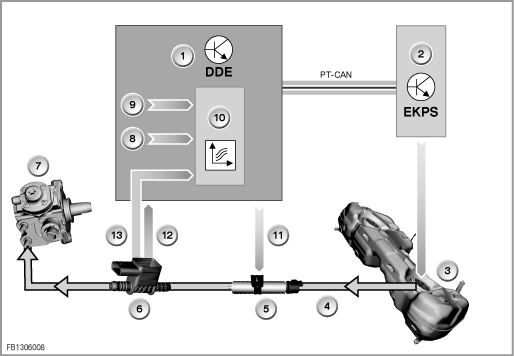

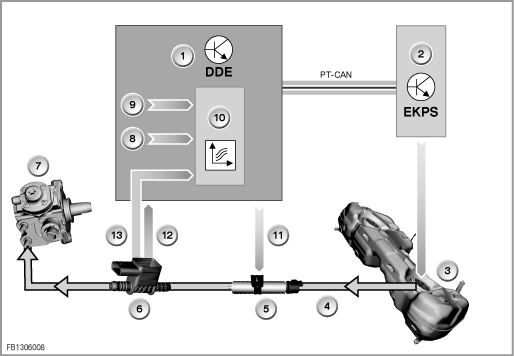

Fig. 1: overview of fuel supply system with presupply control

1 |

DDE control module |

8 |

Input signal engine speed |

2 |

EKPS control module |

9 |

Input signal fuel injection rate |

3 |

Fuel tank |

10 |

Function of the presupply control |

4 |

Fuel feed line |

11 |

Activation of the fuel heater |

5 |

Fuel filter with fuel heater |

12 |

Fuel temperature signal |

6 |

Fuel pressure / temperature sensor |

13 |

Pre-delivery pressure signal |

7 |

High-pressure pump |

|

|

The fuel pressure / temperature sensor is located in the fuel feed line just before the high-pressure pump. The fuel pressure / temperature sensor measures the current actual pressure in the presupply system and sends the signal to the DDE control module. For other functions in the DDE, the fuel pressure-temperature sensor also measures the fuel temperature.

The fuel pump control receives the adjusting value of the regulating circuit from the DDE as a CAN message. The value of the CAN message is converted via a characteristic curve into a voltage in the fuel pump control. This voltage is used by the fuel pump control to activate the electric fuel pump.

The electric fuel pump is activated by the fuel pump control with a voltage of 6.5 - 15 V.

For correct monitoring of the power consumption of the electrical fuel pump, an adaptation value is saved in the DDE control module. The electrical power consumption of the fuel pump at minimum activation is saved with this adaptation value. The lower limit value for monitoring the power consumption of the fuel pump is calculated with this adaptation value.

The electrical fuel filter heating is integrated in the fuel filter and is activated by the DDE control module.

The fuel filter heating is switched on when:

The control of the pre-delivery pressure is monitored by the DDE. Faults that occur due to control deviations are saved in the fault memory of the DDE.

Activation of the electrical fuel pump is monitored by the fuel pump control. Faults that occur here are saved in the fault memory of the fuel pump control.

When the DDE control module is wakened by a wake-up signal, the electric fuel pump is briefly activated for 10 ms.

When terminal 15 is switched on, the electric fuel pump is not activated. The electric fuel pump is only activated on actuating the starter motor.

Resetting the adaptation for electric fuel pump

If the electric fuel pump adaptation must be reset if the high-pressure pump is replaced.

The reason is that the high-pressure pump has a major influence on the power requirement of the electrical fuel pump.