The tolerances given to the injectors on manufacture mean that the actual injected volume of fuel deviates slightly from the theoretically calculated volume of fuel. These injection volume tolerances are determined for each injector across the entire operating range following manufacture by measurements at the suppliers. From these measurements, an calibration value is generated for each injector.

During vehicle assembly, after installation of the DDE control module, the calibration value of each installed injector is saved in the DDE control module. The calibration values are allocated to the individual cylinders according to the installation of the injectors.

The injection volume calculated by the DDE control module during engine operation is corrected slightly by these calibration values thus improving the exhaust emissions.

The service function can be used to change the calibration values of the fitted injectors in the control module and save new values.

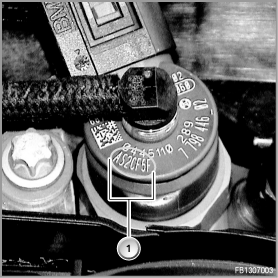

This calibration value is stamped on the top of each injector, see illustration below.

Fig. 1: Example of calibration value for solenoid valve injectors

Important: If injectors have to be replaced, it must be ensured that the stamped calibration value of each injector is assigned to the right cylinder in the DDE control module.

Note: For cylinders for which no new calibration value is entered, the old calibration value is retained in the DDE control module.

Caution: If the DDE control module has been replaced, the injector volume calibration also has to be carried out so that the calibration values of the fitted injectors are saved in the new control module!